MSHK ENGINEERING

We Are Best In Palm Oil Industries Solutions

MSHK ENGINEERING SDN. BHD. was incorporated on the 24th August 1990. Our Company is principally involved in the fabrication and maintenance of palm oil milling plant and machinery, distribution of palm oil milling machinery parts and hardware.

Based on our knowledge, experiences and facilities, we have been awarded to undertake government and private sector projects mainly on palm oil mills. We are fully integrated with turnkey contractor that capable of undertaking:

- the engineering and construction of palm oil mills

- design and manufacturer of palm oil milling plant & machinery

- maintenance & upgrading of palm oil mills

MSHK also has certified Quality Management System underlying our commitment to meeting customer’s product quality requirements.

One Stop Fabricator Solution

Project Management

Testing & Commissioning

Fabrication

Upgrading & Maintenance

Supervision & Erection

Steel Casting

34

yr+

Experience

19000

m2

Factory Size

600

(t)

Component Produce

1200

+

Customer Worldwide

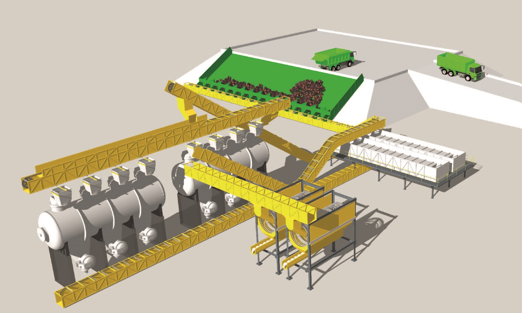

Multidoor System Horizontal Kinetic Sterilizer

Engineered for superior efficiency and product quality, our patented unfired pressure vessel enhances sterilization uniformity, reduces downtime, and integrates seamlessly with your mill operations.

High-Capacity Design

Horizontal configuration allows maximum filling volume with minimal compaction.

Efficient Steam Distribution

Ensures uniform sterilization and prevents FFA formation in crude palm oil.

Automated Buffer Control (ABC) System

Maintains continuous feed to digesters for uninterrupted processing.

Automated Condensate Removal (ACR)

Enhances steam penetration and stabilizes vessel conditions automatically.

Shorter Turnaround Time

Reduces cycle downtime by efficiently buffering sterilized fruit bunches.

Integrated Smart Control

Fully synchronized with sterilization control programs for optimized performance.System Integration Overview

The sterilizer integrates seamlessly with the ABC and ACR systems to ensure a smooth and continuous process flow from sterilization to pressing, maximizing operational efficiency.